Private LTE Devices Enhance Manufacturing Automation

Background

The manufacturing industry is increasingly reliant on advanced technologies to improve efficiency, reduce costs, and enhance safety. With the integration of the Internet of Things (IoT), robotics, and big data analytics, manufacturers require robust and reliable communication networks.

advanced technologies to improve efficiency, reduce costs, and enhance safety. With the integration of the Internet of Things (IoT), robotics, and big data analytics, manufacturers require robust and reliable communication networks.

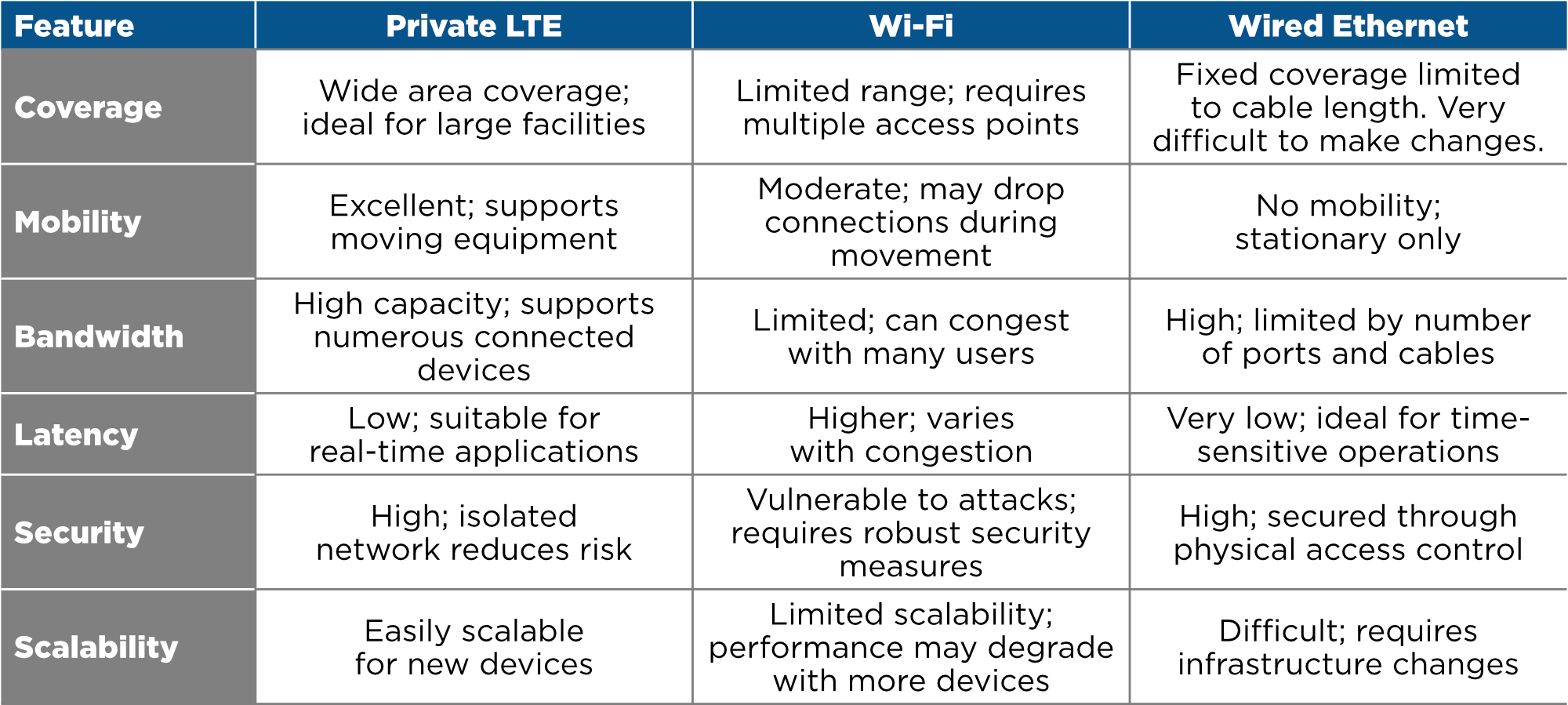

Traditional networking solutions such as Wi-Fi and wired Ethernet often struggle to meet the demands of modern manufacturing environments, particularly in terms of coverage, flexibility, mobility and latency. Private LTE (Long-Term Evolution) networks provide a dedicated, high-performance alternative that addresses these challenges and supports the automation of manufacturing processes.

Challenges

Manufacturers face several challenges in achieving seamless connectivity across their operations:

• Inconsistent Connectivity:

Wi-Fi networks can suffer from coverage gaps and congestion, particularly in expansive facilities filled with machinery and equipment. This can lead to communication disruptions among devices, resulting in downtime and inefficiencies.

• Limited Mobility:

Automated systems, such as robotic arms and automated guided vehicles (AGVs),

require reliable mobility. Wi-Fi can be unreliable in fast-moving scenarios, causing delays in data transmission.

• Security Concerns:

Wi-Fi networks are often more vulnerable to external attacks, which can compromise sensitive operational data. In contrast, wired Ethernet, while secure, limits mobility and flexibility.

• Scalability Issues:

As manufacturers adopt new technologies, scaling Wi-Fi and wired Ethernet can be

cumbersome and costly, requiring extensive infrastructure changes.

Solution

Implementing a Private LTE network with MultiTech routers, bridges, and modems offer a comprehensive solution to these challenges by providing:

• Robust Coverage:

Private LTE networks can cover large areas with consistent connectivity, ensuring that all devices, regardless of location, can communicate without interruption.

• High Mobility:

Designed for mobility, Private LTE supports devices in motion, allowing for real-time data transmission even as equipment moves throughout the facility.

• Enhanced Security:

Private LTE networks operate in a dedicated spectrum, isolated from public networks.

This isolation minimizes the risk of cyberattacks and protects sensitive manufacturing data.

• Scalability and Flexibility:

Private LTE networks are highly scalable, allowing manufacturers to easily add new devices and technologies without significant infrastructure changes. This adaptability supports ongoing innovation and expansion.

MultiTech Private LTE Devices

MultiConnect® rCell 500 Series Private LTE CBRS Industrial Cellular Router

MultiConnect® rCell 500 Series Private LTE CBRS Industrial Cellular Router

Extends the reach of private LTE CBRS networks into remote sites that require reliable wireless mobile broadband performance. Enterprise equipment connects using industrial Ethernet, Serial, USB, GPIO interfaces and built-in Wi-Fi, all managed remotely through the MultiTech DeviceHQ® service. Seamless failover capabilities provide customers the added confidence needed when system disruption is not an option

MultiConnect® eCell Private LTE CBRS Cellular to Ethernet bridge

Add private LTE connectivity to existing wired assets quick and easy. Provides primary or secondary (wireless failover) network access to surveillance cameras, building management systems, Wi-Fi access points, digital signage, autonomous mobile robots and always-on IP connectivity.

MultiConnect® microCell Private LTE CBRS USB Cellular Modem

A compact communications device that makes adding private LTE connectivity to existing assets quick and easy. Use in settings such as vending, control systems, digital signage, smart parking, smart inventory, audio devices, notebooks and tablets. With LTE Cat 6 CBRS OnGo shared wireless spectrum, the MultiConnect microCell has more than enough speed to meet the needs of almost any IoT application.

Benefits

Enhanced Connectivity

Private LTE provides reliable, high-speed connectivity throughout manufacturing facilities, eliminating the disruptions associated with traditional Wi-Fi. This reliability minimizes downtime and enhances the performance of automated systems, resulting in increased operational efficiency.

Improved Automation

With low latency and high bandwidth, Private LTE enables real-time data collection and analytics. Manufacturers can optimize production schedules, manage inventory effectively, and implement predictive maintenance strategies. Automated systems can respond instantly to changes in the production environment, driving higher output and reducing waste.

Increased Security

The enhanced security features of Private LTE networks safeguard sensitive data and operational technology. By operating on an isolated network, manufacturers can protect against cyber threats and ensure compliance with industry regulations.

Scalability and Future-Proofing

Private LTE networks are designed to be easily scalable, accommodating new devices and technologies without extensive modifications. This flexibility enables manufacturers to adapt to evolving market demands and incorporate innovative solutions, ensuring long-term competitiveness.

Private LTE Compared to Wi-Fi and Wired Ethernet

Conclusion

Private LTE networks represent a transformative solution for enhancing manufacturing automation. By providing robust coverage, high mobility, enhanced security, and scalability, Private LTE effectively addresses the limitations of traditional Wi-Fi and wired Ethernet solutions. As manufacturers continue to embrace digital transformation, the implementation of Private LTE will play a crucial role in optimizing operations, reducing costs, and driving innovation in the industry.